The stiffness of a building has a significant effect on the elements attached to the façade of the building and can affect the appearance and cost of a building envelope solution. A light flexible structural frame may save money on the primary frame costs, but can have a detrimental effect on other elements that must be designed to accommodate potentially large movements. This affects not only external façade elements such as glass aluminium or terracotta tiles, for example, but also the junction designs of pre-cast and other external materials as well as internal elements such as glass partitions and heavy mechanical plant systems.

A building façade system, if correctly designed and installed, will ensure safe seismic performance under design accelerations. Depending on the movement the building experiences and the engineered tolerances allowed, a façade will continue performing, won't evacuate from the building, and require little or no removal, refurbishment, repair or replacement after an event.

Light vs Heavy Façades

The relatively light weight nature of materials that are commonly employed in total clad solutions such as glass and aluminium, which can have the appearance of architectural pre-cast concrete, make them particularly suitable in earthquake-prone regions, along with potentially reducing cost on primary structure due to reduced weight and acceleration loading.

A pre-cast system wall panel typically spans from floor-to-floor: horizontal drift or deformation of the building structural frame can create considerable racking forces in panels that are rigidly attached at top and bottom, resulting in damage or possible drop-off. Therefore the attachment of these panels must permit differential movement of the floors without transmitting racking forces to the panels. This is achieved by special detailing of the connection of panels to structure.

Engineered unitised panels or curtainwalls that span from floor-to-floor offer greater flexibility, lighter weight and resilience rendering the problem less severe. Even typical framed window glazing inserted in structural walls is potentially subjected to racking problems.

The evolution of seismic design methods in cladding design and their attachment has been accomplished through specific design to meet project requirements by our experienced in-house façade and structural engineers.

Wind Action

Movement in façades is not limited to earthquakes. Other building live loads such as wind is also a major factor in frame and glazing design. The seismic problem is primarily that of protection from in-plane forces whist that of wind is primarily concerned with out-of plane effects. The design of effective resilient glass retention systems contributes to the solution of both.

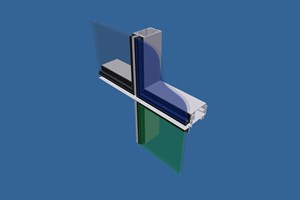

Cavity Construction

Rainscreen cladding systems that are designed with rigid air barriers need to be designed and tested to allow for joints that are subjected to shear, compression and elastic stretching that will reset and not fail and become vulnerable to air leakage, and subsequent water penetration resulting in durability problems.

Seismic Joint Design

Thermosash designs and engineers seismic joint systems that integrate into our cladding and curtainwall systems to provide a totally integrated solution.

Section Sizes

Seismic sections will vary depending on the project's specific engineered calculated limit states (SLS / ULS). These can vary significantly from project to project and a highly flexible building may require significant specialised envelope design to compensate for the primary structure movement.

Specification

Thermosash's branded specifications cover seismic receivers. Please find the links below to the following specifications:

Surface Finishing

As seismic receivers are generally visible they require surface finishing and we recommend the following:

- Polyester powdercoat - Both standard and special colours available.

- Anodised - All anodised colours available - commercial grade 20 micron finish recommended.

- PVF2 Flourocarbon finishes - Available on request.

Performance / Testing

- AS/NZS1170 (Structural Design Actions

- NZS4223 (Glazing in Buildings)

- NZS/AS4284:2008 (Water / Air Pressure/ Air Leakage - Meets and exceeds minimum requirements)

Warranty

The standard warranty is 5 years from the date of practical completion for these products. This covers workmanship and weather tightness, providing the subcontract includes fabrication, installation and glazing of all components.