PW40

Product Description

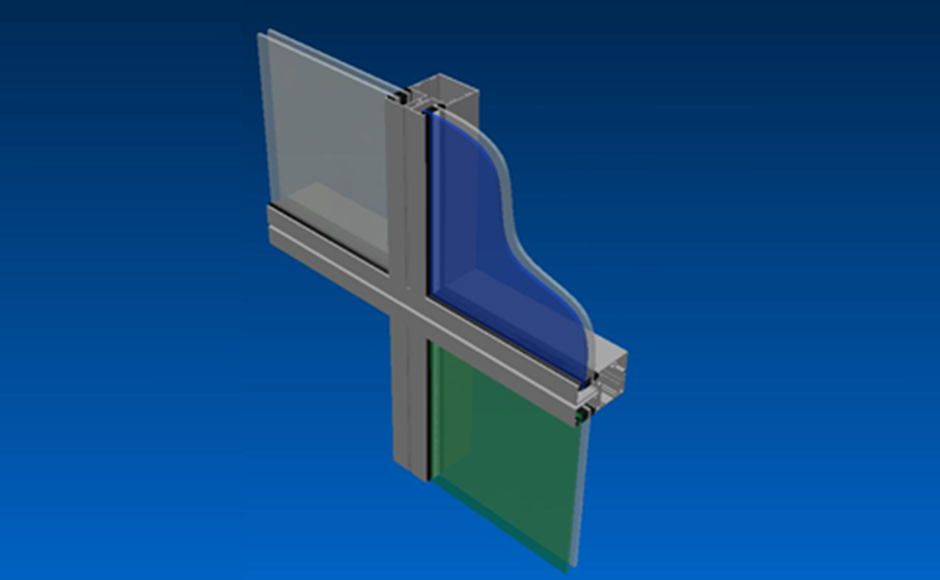

Thermosash PW40 : is a four sided mechanically glazed engaged curtainwall, that is; expressed horizontal transom elements and vertical mullion elements - offering a similar appearance to the high performance PW400.

This unitised curtainwall suite is suitable for low or high rise applications where small spans or where smaller panes of glass are envisioned. The PW Series Suites have been extensively used and proven in New Zealand and our export markets since 1985.

Section Sizes

- 75 / 100mm Mullions

- 75 / 100mm Transoms

Maximum spanning ability

The spanning ability will vary depending on the structural system and environmental loads (e.g. wind). Thermosash specifically engineers the best suite options to meet project requirements.

PW40 is best used for:

- Lower floor to floor heights - greater heights are achievable with our PW400 suite

- Sites with low wind loads

- Smaller module sizes

- Areas where there is low building movement

Low carbon aluminium - specify Thermosash DecarbalTM

Our Thermosash DecarbalTM aluminium achieves a very low carbon footprint that significantly outperforms readily available local & global alternatives - offering reduced upfront carbon emissions that positively contribute to sustainability project goals. For up-to-date carbon figures please contact us. Find out more about our Sustainable Aluminium.

We recommend discussing your project with us early so that we can advise on the best suite solutions for your needs - please contact us.

Relevant Projects

Novotel Christchurch Airport Hotel

Christchurch

Warren & Mahoney Architects

Fletcher Construction

2019