PW1000-TB200 Thermal Break

Product Description

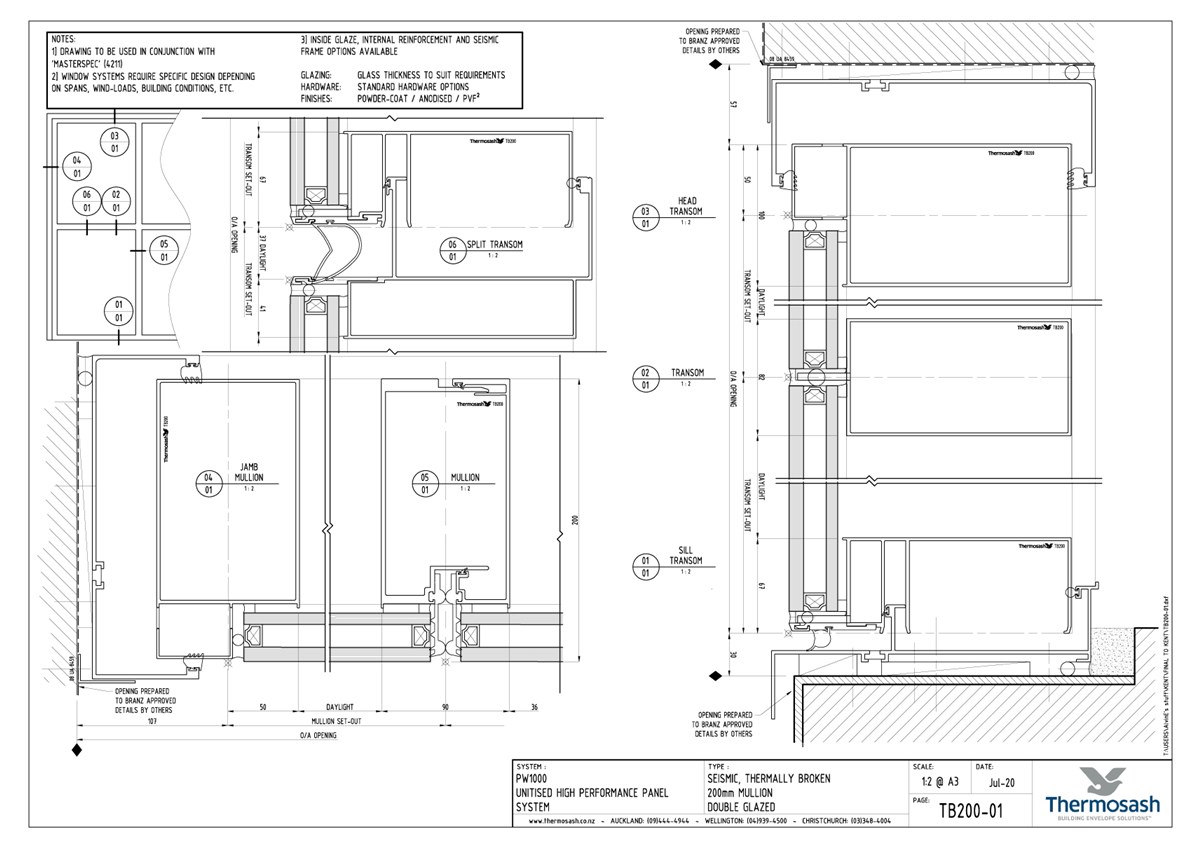

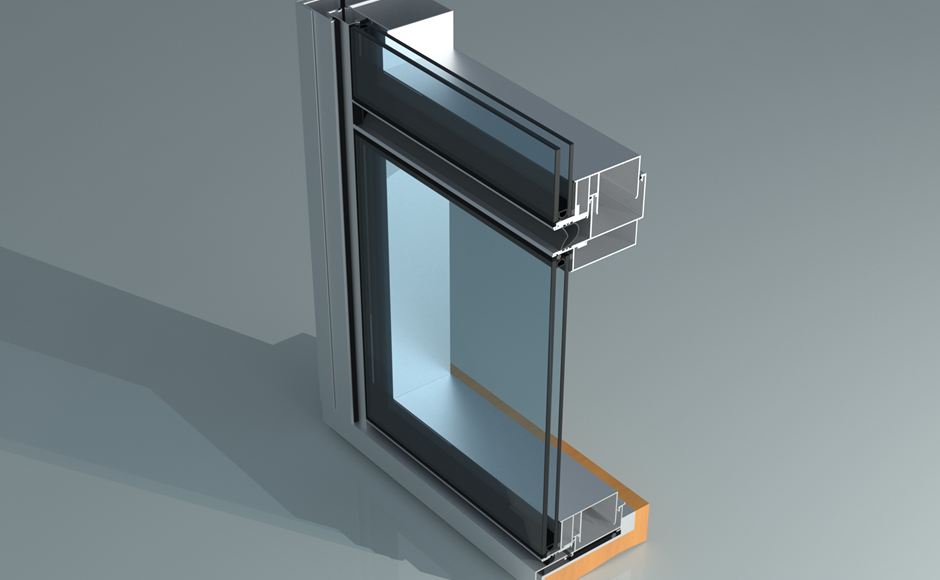

Thermosash PW1000-TB200 : Thermally broken four sided mechanically glazed engaged curtain wall - both horizontal transom, and vertical mullion elements are expressed.

Thermosash thermally broken unitised engineered low-carbon aluminium systems offer exceptional thermal efficiency, as well as longevity in product life span minimising maintenance costs and maximising the return on invest on the facade of the building.

Mullion Size: 200mm

Performance

The calculated thermal performance of the curtainwall / panel wall suite is subject to many variables, from size of individual panels, glass performance, introduction of transoms and integrated solar shading (where bracketing may cause a cold link passage) and the spandrel depth (insulation).

Performance glass

It is important to note that the aluminium section alone does not provide the thermal performance often expected. Glass specification is a significant contributor to the overall mechanical performance requirement of a building. The larger the glass pane the better performing the panel will be on average. Thermosash has access to suppliers of low carbon high performance glazing and can deliver an integrate solution.

Engineering Custom solutions

Thermosash design and detail the facade solution to meet project demand for seismic risk, wind loads, climate zones, corrosion zones and building importance levels as well as aesthetics, unique site constraints and budgetary requirements. We have extensive experience in integrating our systems and products to deliver a total facade solution.

Low carbon aluminium

Our aluminium achieves a very low carbon footprint that significantly outperforms readily available local & global alternatives - offering reduced upfront carbon emissions that positively contribute to sustainability project goals. For up-to-date carbon figures please contact us.

Carbon reports

Via our in-house thermal engineers and custom-built calculators, we can assess and provide facade thermal, embodied and operational carbon reports to assist in guiding design and calculate a ROI on facade suite selection.

Unitised pre-fabrication

Our systems are prefabricated and glazed at our manufacturing facilities (Auckland, Wellington and Christchurch) and can be transported for just-in-time site delivery. Due to prefabrication and the unitised modular design of our products and systems our highly skilled installation teams can close in buildings rapidly saving on programme time and mitigate follow on trade risk.