Thermosash Alpha Glazing System

Product Description

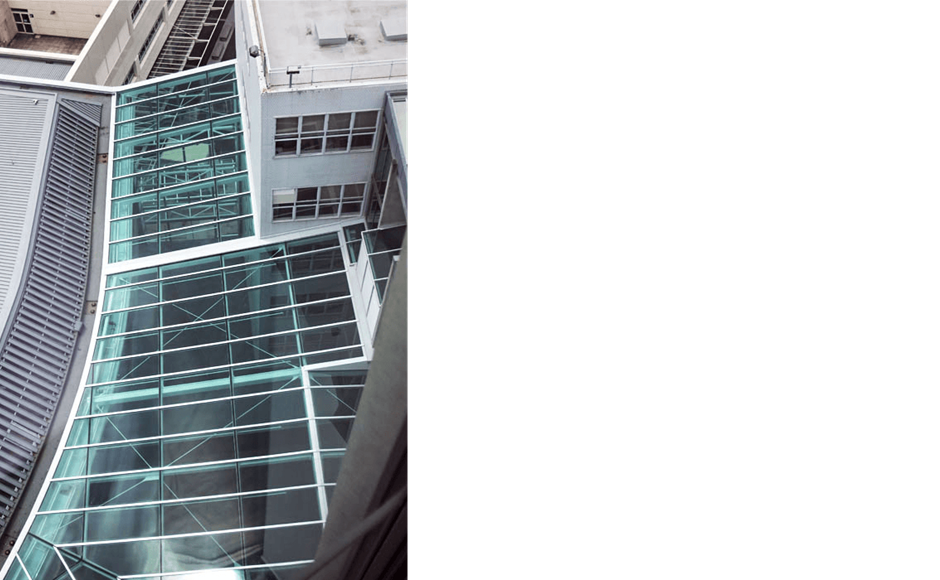

Thermosash has extensive experience engineering, manufacturing and installing rooflights, atrium glazing and canopies for commercial buildings.

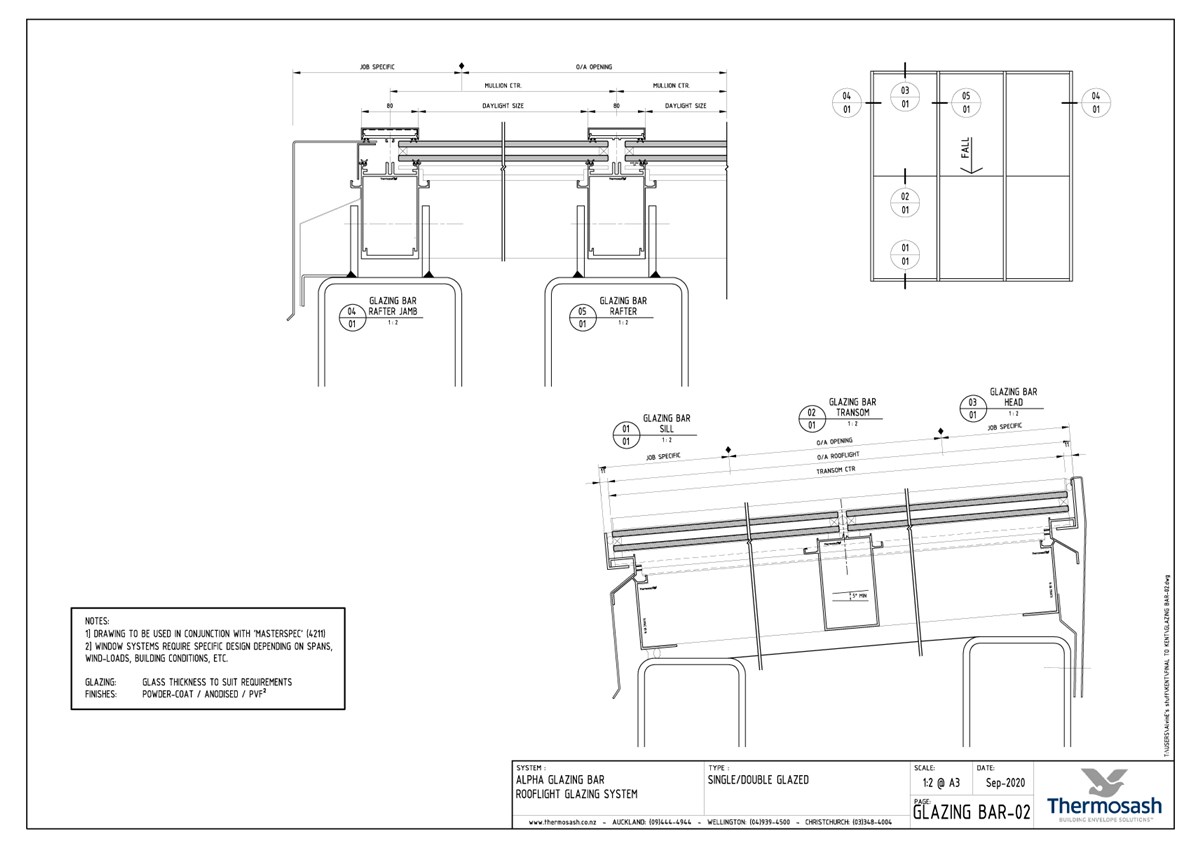

The Thermosash Alpha Glazing System is a capped, skylight & atrium glazing bar system. This design style of overhead glazing employs an aluminium extrusion that encapsulates a minimum of two edges that are then connected back to the primary structure.

The Thermosash Alpha Glazing Suite can be used externally for canopies or internally for skylights as a sophisticated and high-performance solution for all high-end sloped glazing applications. The system also offers an economical solution for factories, warehouses, hangers and grandstands.

Engineering

Due to potential exposure to high wind, seismic, snow, and live loads etc, it is necessary for these types of systems to be specifically designed and engineered. The sophistication required of products used in overhead glazing can often be overlooked; special design features are required to cope with and overcome considerably higher water loadings, heat gain or loss (which introduces condensation) and in particular the risk associated with accommodating costly higher specification products (e.g. high performance laminated and insulated glass units) without compromising their product warranties.

Innovation and providing custom specific design solutions has always been the foundation on which Thermosash has developed its suites. Our growth has been influenced by constant research and development and being aware of overseas trends.

Overhead glazing configurations include:

- Lean-to skylights

- Ridge skylights

- Double pitch skylights

- Pyramid skylights

- Multi-facetted pyramids

- Hip ridge skylights

- Segmented barrel vault skylights

- Curved barrel vault skylights

- Vertical glazing

Section Sizes: range of 55mm - 80mm

Integrated elements

- Alpha Glazing System integrates with the Thermosash Delta Suite.

- The Alpha range can incorporate opening sashes or banks of louvres - BMS operated if required.

- Almost any type of glass can be incorporated including ceramic fritting to provide an element of solar shading or decorative motif.

Low carbon aluminium - specify Thermosash DecarbalTM

Our Thermosash DecarbalTM aluminium achieves a very low carbon footprint that significantly outperforms readily available local & global alternatives - offering reduced upfront carbon emissions that positively contribute to sustainability project goals. For up-to-date carbon figures please contact us. Find out more about our Sustainable Aluminium.

Relevant Projects

Wellington International Airport - The Rock

Wellington

Warren & Mahoney - In association with Studio Pacific Architecture

Mainzeal

2010