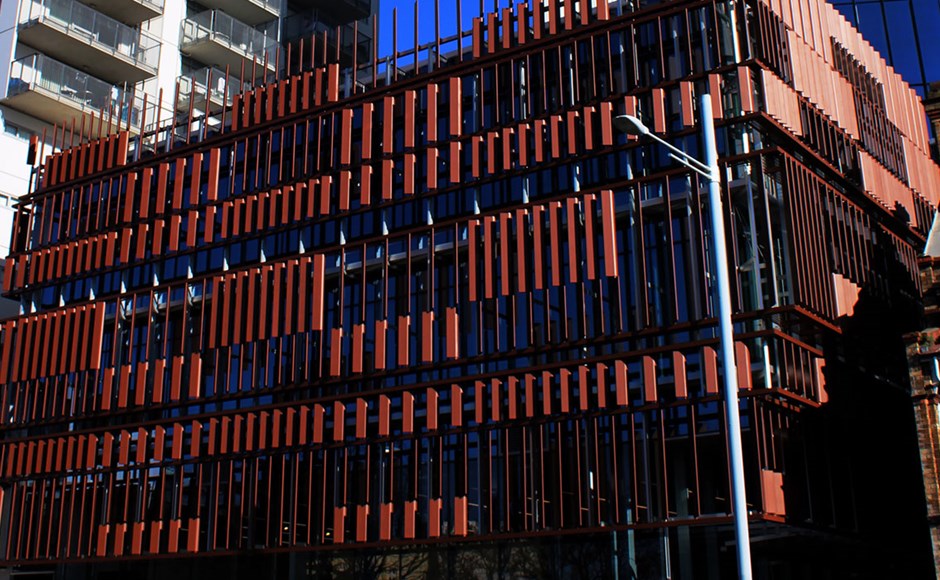

Extruded & Composite Louvres

Product Description

The added advantage of a Thermosash louvre system is you design it - Thermosash engineers it! Our in-house engineers deliver bespoke solutions while maintaining architectural aesthetic intent. With our local manufacturing in Auckland, Wellington and Christchurch we have the capabilities to cover projects across New Zealand.

Blades: The blades can be custom clad with almost any durable material. Sizes range from 90mm up to 1200mm - all able to be integrated into our façade suites without the need for additional structure by other trades. The blade systems can be fixed or actuated via integrated BMS functions offering a high-quality external building shade system that can lower the heat gain on your building and add aesthetic value.

Section Sizes

Contact us to discuss your design requirements.

Low-Carbon Aluminium

Thermosash partners with a local NZ-owned extruder achieving a lower carbon footprint than the global average - offering reduced upfront carbon emissions. (find out more about our Sustainable Aluminium).

Aluminium is 100% recyclable, and the aluminium from our manufacturing process that is not powdercoated is environmentally managed back to our key suppliers and processed back into raw billet form.