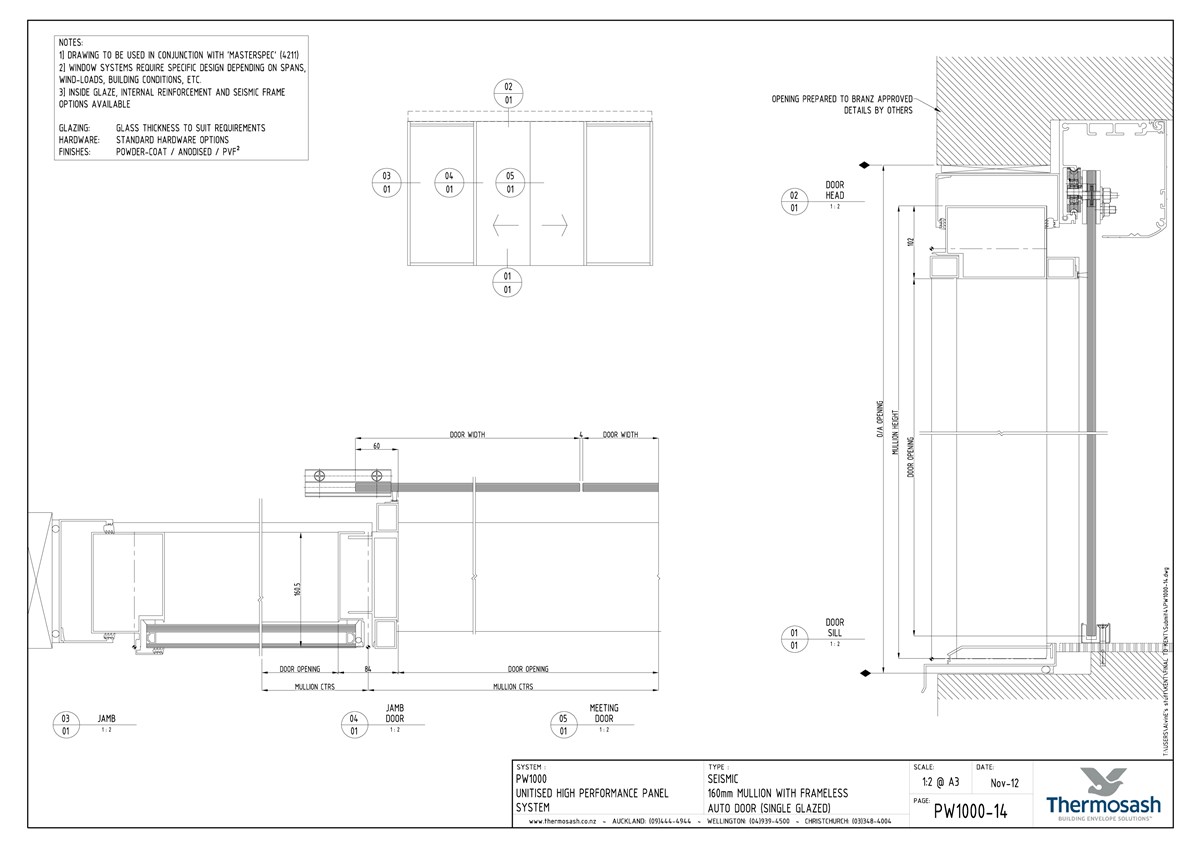

PW1000

Product Description

Thermosash PW1000: four sided structurally glazed curtainwall suite designed for high-rise or lowrise applications where the project has large spans or large panes of glass requiring higher strength systems.

The suite has been extensively used and proven in New Zealand and our export markets since 1985. The advantage of this system is, whilst it utilises a mullion and transom system internally to hold the glass or other elements, the surface is generally free from any visible aluminum structural element - providing a smooth glass face.

Mullion Sizes: 75mm / 100mm / 150mm / 200mm

We have the ability where necessary, to structurally supplement the sections when the suite is exposed to high floor to floor spans or high wind zones, thus potentially reducing the need for additional primary or secondary structure to be provided by the Main Contractor.

Maximum Spanning Ability

The spanning ability will vary depending on the structural system and environmental loads (e.g. wind). Thermosash specifically engineers the best suite options to meet project requirements.

Thermosash Suites are recognized as having the largest spanning systems on the market due to our specific engineering capability and the customised nature of the work we complete.

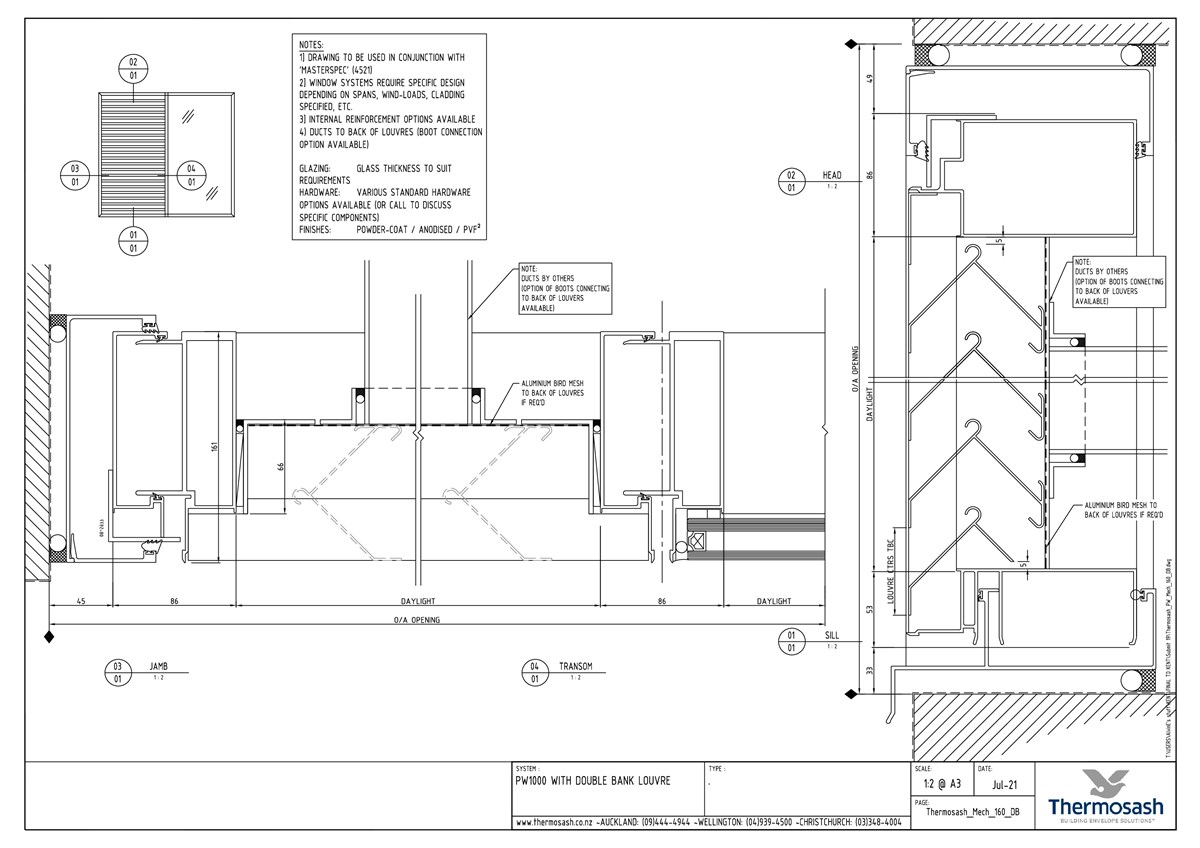

Integrated Elements

- brackets to receive externally mounted fins, louvres, Venetians, custom feature elements, or building signage

- opening sashes suitable for high-rise installations can be accommodated

- a large variety of materials can be integrated into a unitised panel, including:

-

- different glass types

- metals

- terracotta tiles

- large format porcelain

- glass reinforced concrete (GRC)

Engineering Custom solutions

Thermosash design and detail the facade solution to meet project demand for seismic risk, wind loads, climate zones, corrosion zones and building importance levels as well as aesthetics, unique site constraints and budgetary requirements. We have extensive experience in integrating our systems and products to deliver a total facade solution.

Low carbon aluminium - specify Thermosash DecarbalTM

Our Thermosash DecarbalTM aluminium achieves a very low carbon footprint that significantly outperforms readily available local & global alternatives - offering reduced upfront carbon emissions that positively contribute to sustainability project goals. For up-to-date carbon figures please contact us.

Thermosash partners with a local NZ-owned extruder achieving a lower carbon footprint than the global average - offering reduced upfront carbon emissions. (find out more about our Sustainable Aluminium).

Facade Optimisation and Sustainability Reports

To achieve optimised high-performance outcomes, we offer our clients the option of a Project Sustainability Analysis that covers different aspects of the full sustainability cycle. When specifying our facade systems, clients can engage us to implement one or several of our Facade Optimisation Strategies to achieve their project sustainability goals. To gain the most from our strategies, talk to us early on in the design phase of your project.

Relevant Projects

Tākina Wellington Convention and Exhibition Centre

Wellington

Studio of Pacific Architecture

LT McGuinness

2022

Mobil Exxon Project - Papua New Guinea

Papua New Guinea - Port Moresby

Kellogg Brown & Root Pty Ltd (Principal Design Consultant)

Leightons

2015