WS1000

Product Description

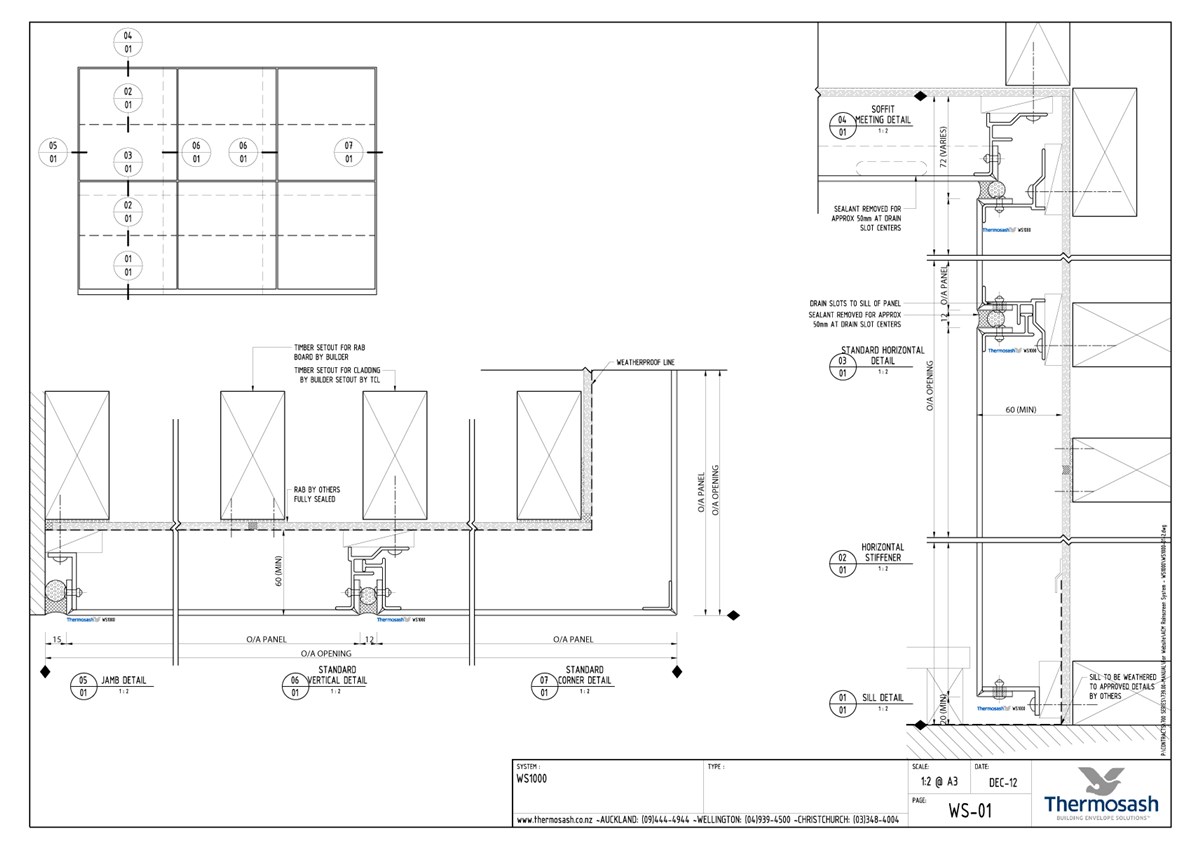

WS1000 suite - The Thermosash Fully Flushed Sealed Joint Cladding - is an engineered cavity rainscreen cladding system, incorporating a unique cavity creating bracketing system. The suite most commonly utilises ACP (Aluminium Composite Panel) as the rainscreen material, but equally also can incorporate almost any other solid metal or ACP type material, such as a cassette cartridge in zinc, stainless steel, terracotta or powder coated aluminium etc.

Rigid Air Barrier

The WS1000 suite requires a formed air barrier wall (Rigid Air Barrier - RAB) located behind with a suitably considered primary structure (concrete panel, timber or steel framing) to receive the cladding rail system. The system joints are flush sealed with silicone providing the opportunity to overclad buildings and provide a modern sophisticated appearance for a relatively low cost where an existing durable wall already exists. A typical installation will require external access such as scaffolding and is best suited to lowrise applications due to the limitations of RABs in multi-storey applications.

Section Sizes

The designer should allow a zone from the face of the air barrier of 60mm.

Panel size limitations are calculated on the project location (wind zone / seismic), height, primary structure movement calculations (ULS) and eventual material selection.

Relevant Projects

Wellington Regional Children's Hospital

Wellington

Studio Design + Architecture

McKee Fehl Constructors

2022

Toyota HQ - Palmerston North

Palmerston North

Woodhams Meikle Zhan Architects

Humphries Construction

2022